August 29, 2025

6mm GT 35 Reloads Test

A big conversation piece in any precision rifle circle, or a group of hunters that load their own ammo is the topic of brass casings. Shooters talk about dimensions, consistency, performance, fit and finish, and one of the biggest topics, how long will those casings last? Shooters today set out to get more for their hard-earned money. Let’s face it, this sport is expensive. From your rifle, optics, and ammunition, whether you load your own ammo or buy factory loaded ammo off the shelf, your wallet gets very comfortable with being uncomfortable. So, what can we do to help the everyday shooter financially, and help them with their results down range? Our answer to that question is to produce extremely high-quality brass casings that last seemingly well beyond the life of the rifle barrel that is screwed into the action that you are currently shooting. Here at Peterson Cartridge, we set out to produce casings that are as consistent as possible with our current production technology. This aides the shooter in load development making it easy and quick to work up a load with a simple ladder test using minimal components to accomplish the task. We also strive to make some of the most durable casings on the market today. There have been many tests done on our casings to see just how many reloads you can get out of a particular caliber. There are also a lot of variables in those tests so we decided to run a test of our own to see just how far we can push one of our new 6mm GT casings before it fails. This article will outline the results of that test, and what we saw as the testing progressed.

To start, we needed to decide where we planned to run the test on the pressure spectrum. We picked a load that was on the higher end of the pressure tolerance when using Hodgdon’s Varget powder and Sierra’s 107 grain match king bullet. The powder charge was 33.2 grains, and we loaded to 2.600 overall length for the entire test. Our reasoning was such that if we were going to test how robust our casings are, we should do it at a high-pressure load to give us good representation and data for what the casing can withstand.

To start, we needed to decide where we planned to run the test on the pressure spectrum. We picked a load that was on the higher end of the pressure tolerance when using Hodgdon’s Varget powder and Sierra’s 107 grain match king bullet. The powder charge was 33.2 grains, and we loaded to 2.600 overall length for the entire test. Our reasoning was such that if we were going to test how robust our casings are, we should do it at a high-pressure load to give us good representation and data for what the casing can withstand.

Our next choice was the rifle. We decided to use a factory rifle for this test instead of a custom-built rifle due to the fact that factory rifles tend to be a bit more loose on the chamber specs over a custom. This has a negative effect on the casings causing more brass movement on the initial firing. This, in theory, should cause case failure to some degree, sooner. The more you work the brass the less life you get out of a casing.

Our rifle of choice was the Bergara Premier Competition Rifle. This rifle features a Masterpiece

Arms chassis, Bergara’s Action and one of their heavy contoured barrels. Bergara has been known for a long time in the precision rifle world to produce great barrels and rifles. They are one of the best options for an “off the shelf” rifle that you can purchase at your local gun shop.

The last part of the test was to establish our reloading practice. What dies to use? How much sizing would be done between each loading? What case lube to use? Do we anneal between each firing?

We wanted to use a very common set of dies that a lot of reloaders are using today. We felt that this would be a better representation of what the masses are using. We picked a set of Hornady Custom Grade dies to run the entire test. The sizing die was set up for a .002 shoulder bump which has been the standard for a long time. We used Sinclair sizing wax for the test as well. The sizing wax is used by many shooters so staying in tune with common equipment, the sizing wax was an easy choice.

We also made the decision not to anneal after each firing. This decision was made to see just how far the casing would go for someone without a way to anneal their brass. We also wanted to see how this affected sizing as we moved through the testing cycle.

Test Day

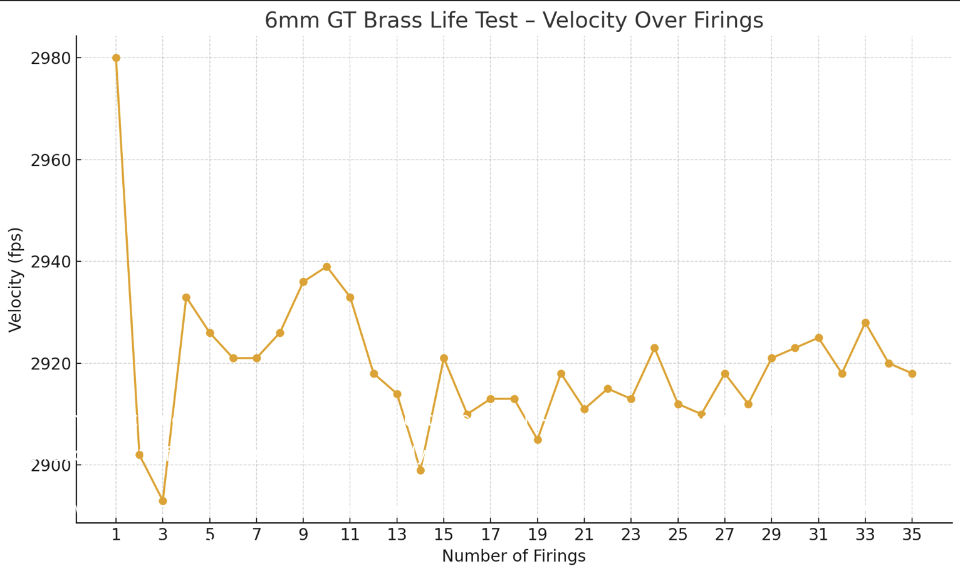

We began our test by giving our casing a light chamfer and debur of the mouth and got started loading. Our first firing generated a speed of 2,980 feet per second and I will list the velocity of each firing as we progressed. It is important to note that the rifle had been broken in and thoroughly cleaned prior to the testing.

The test ran as follows in velocity.

Our rifle of choice was the Bergara Premier Competition Rifle. This rifle features a Masterpiece

Arms chassis, Bergara’s Action and one of their heavy contoured barrels. Bergara has been known for a long time in the precision rifle world to produce great barrels and rifles. They are one of the best options for an “off the shelf” rifle that you can purchase at your local gun shop.

The last part of the test was to establish our reloading practice. What dies to use? How much sizing would be done between each loading? What case lube to use? Do we anneal between each firing?

We wanted to use a very common set of dies that a lot of reloaders are using today. We felt that this would be a better representation of what the masses are using. We picked a set of Hornady Custom Grade dies to run the entire test. The sizing die was set up for a .002 shoulder bump which has been the standard for a long time. We used Sinclair sizing wax for the test as well. The sizing wax is used by many shooters so staying in tune with common equipment, the sizing wax was an easy choice.

We also made the decision not to anneal after each firing. This decision was made to see just how far the casing would go for someone without a way to anneal their brass. We also wanted to see how this affected sizing as we moved through the testing cycle.

Test Day

We began our test by giving our casing a light chamfer and debur of the mouth and got started loading. Our first firing generated a speed of 2,980 feet per second and I will list the velocity of each firing as we progressed. It is important to note that the rifle had been broken in and thoroughly cleaned prior to the testing.

The test ran as follows in velocity.

As you can see, during the test there were a few patterns in velocity. Early on it was on both the high and low end. The fastest speed recorded was on the first firing at 2980 and the lowest speed recorded was on the 3rd firing at 2893. This could be due to the clean bore that we started with. After our tenth firing, the speeds really calmed down in the 2915 feet per second range for a majority of the test. Once we made it up to 29 firings and beyond our second trimming, the speeds went up and stayed in the 2920’s or close to it for the rest of the testing. Note that we only trimmed the brass when it was absolutely necessary for fitment in the rifle.

Test Sizing Summary

As for the sizing of the brass during the test, it was business as usual all the way to 12 firings. Once we reached number 13, our sizing dropped off from .002 of shoulder bump to .001 or less. After the 13th firing, I began to apply a little more lube to the casing and this brought us back to our .002 shoulder bump. This maintained up to firing #26. Once we sized going into #27, our shoulder bump dropped to .0005 or less and the press stroke felt much different at cam over. We also had to work in a longer pause at the bottom of the press stroke to help mitigate spring back at this point. Despite all this, the casing showed no signs of failure and was still going strong. After we made it to 30 firings, I made a very small adjustment to the die due to a tight bolt close. Our shoulder bump had basically gone away. After the small adjustment, we were able to get back to .0015 of bump so that the casing would fit in the gun without issue. We then ran the rest of the way to 35 firings at this setting with no problems.

The end result

In the end, we were extremely happy with the results of our test. We took a very popular round that is used extensively in competitive shooting and pushed it well beyond the anticipated life of a case. Consistent reloading practice and meticulous processing each time made a big difference in longevity. We were very careful to only work the case as necessary for reliable fitment in the rifle. The less work you do to a casing when reloading, the longer it will last. Plain and simple. At the conclusion of the test, we checked for case head separation internally because the outside of the case did not show any signs of this issue. We found no traces of separation. We then checked the neck and shoulder area for any cracks or defects and aside from a few small ripples in the shoulder area, we found no issues there either. Our last check was purely visual. Our casing had been run rather hard through a rifle 35 times. There were scratches and dings, some carbon on the neck area, and the shoulder was showing the marks from the chamber and the die that was used when sizing. Outside of that, there were no defects that would render the casing unusable. It had survived our torture test and passed with flying colors. Keep in mind that this test was run in a controlled environment where everything was checked and monitored throughout the entire process. Each round was fired in our indoor test range, and we used our velocity screens to monitor speed. Each time the case was fired, it was measured before and after sizing. We also checked for defects every time. Our 6 GT kept coming back for more even after we thought that it was on its last leg. This test was performed to see if your casings could potentially outlast your barrel. I would say without the shadow of a doubt that you could definitely run a barrel to the end of its life on a 50 count box of our 6 GT brass. We know most shooters purchase a lot more than 50 at a time so the potential for your brass to last longer than multiple barrels is very good. If the rifle’s chamber is in spec and the reloader does their part doing the least amount of work they can to those

casings at the bench, the number of reloads will far exceed the barrel life.

Long Live Quality Brass!

By entering this website, you certify that you are 18 years of age or older.